| Withit special mechanical design,SME-24 using the hydrodynamic water fragmentation,producing very finewater mist,with the speed of sound (V = 360m/s) to form a strong momentum jet to the nozzle, nozzle for cleaning at the top of the formation of a continuous field,crushing the internal surface of the dirt (the nozzle will not be damaged because of its independent device),during the cleaning process the used cleaning water (deionized water or distilled water) automatic direct emissions. |

Functions:

|

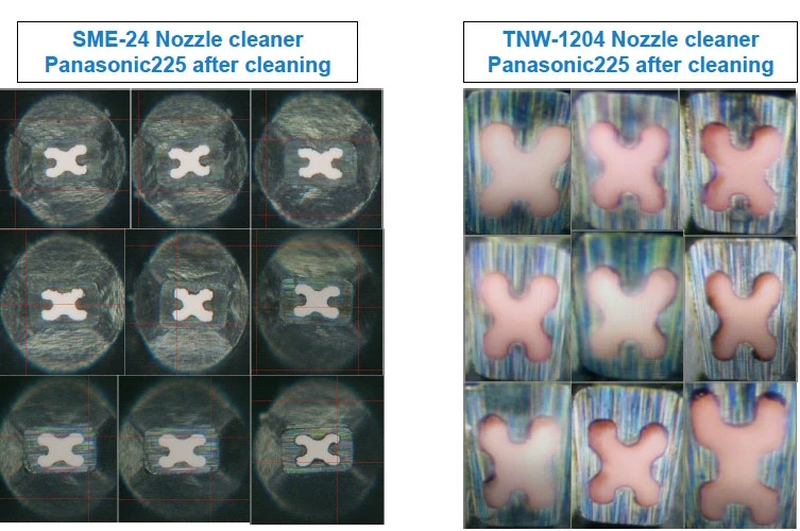

- Thoroughly clean the dirt on nozzles which ultrasonic cleaner can not clean.

- Strong clean power for nozzles ,even the smallest nozzle hole.

- Very good cleaning effectiveness, extend lifespan of the nozzles.

- No damage to the coating layer of the nozzle and its reflector panel.

- Only use DI water or distilled water.

- Auto clean and dry.

- Easy operation.

- Right for all kind of mounter nozzles .

|

Economic Benefits:

|

- To reduce the cost of nozzle:se SME-24 cleaning machine can clean dirty nozzle very well,to prolong nozzle life.

- To reduce labors: As the machine clean full automatically,the machine complete the whole process by itself,so there is no need person in charge of it.

- To reduce reject rate and defective rate of. products effectively,improve SMT productivity:The dirty and uneven nozzle may easy make the production line cast material or mount shift,and cause the poor welding.Use this cleaning machine,it can keep the nozzle always new,greatly improve the production efficiency.

|

Ultrasonic Cleaning Machine

|

- Low cost and high efficiency;

- Nozzlesare easy to collide with each other during cleaning process,thismake the black surface coating damage or fall off;

- The cleaningliquidwill damage the nozzle,greatly shorten the life of nozzle;

- It can not clean nozzle surface and theinner holethoroughly;

- It can not clean the 01005 and 0201 nozzlesverywell,asthe inner hole of nozzle is too small,vacuum bubbles cannot be discharged when using ultrasonic cleaning.

|

Technical Parameters

|

| Item |

SME-24 |

| Clean head |

4pcs |

| Air supply |

0.5~0.7Mpa |

| Power supply |

AC220V,1A |

| Clean liquid |

Distilled water or industrial deionized water |

| Clean time |

2~3min |

| Dry time |

1~3min |

| Spray pressure |

≤0.55Mpa |

| Clean liquid consumption |

≤300cc/hour |

| Nozzle range |

minimum 01005~max inner dia¢2.0mm |

| Jig spec |

Small nozzle 24 hole /large nozzle 12hole |

| Machine size |

L665*W555*H475(mm) |

| Machine weight |

40KG |

|

| |

|

|